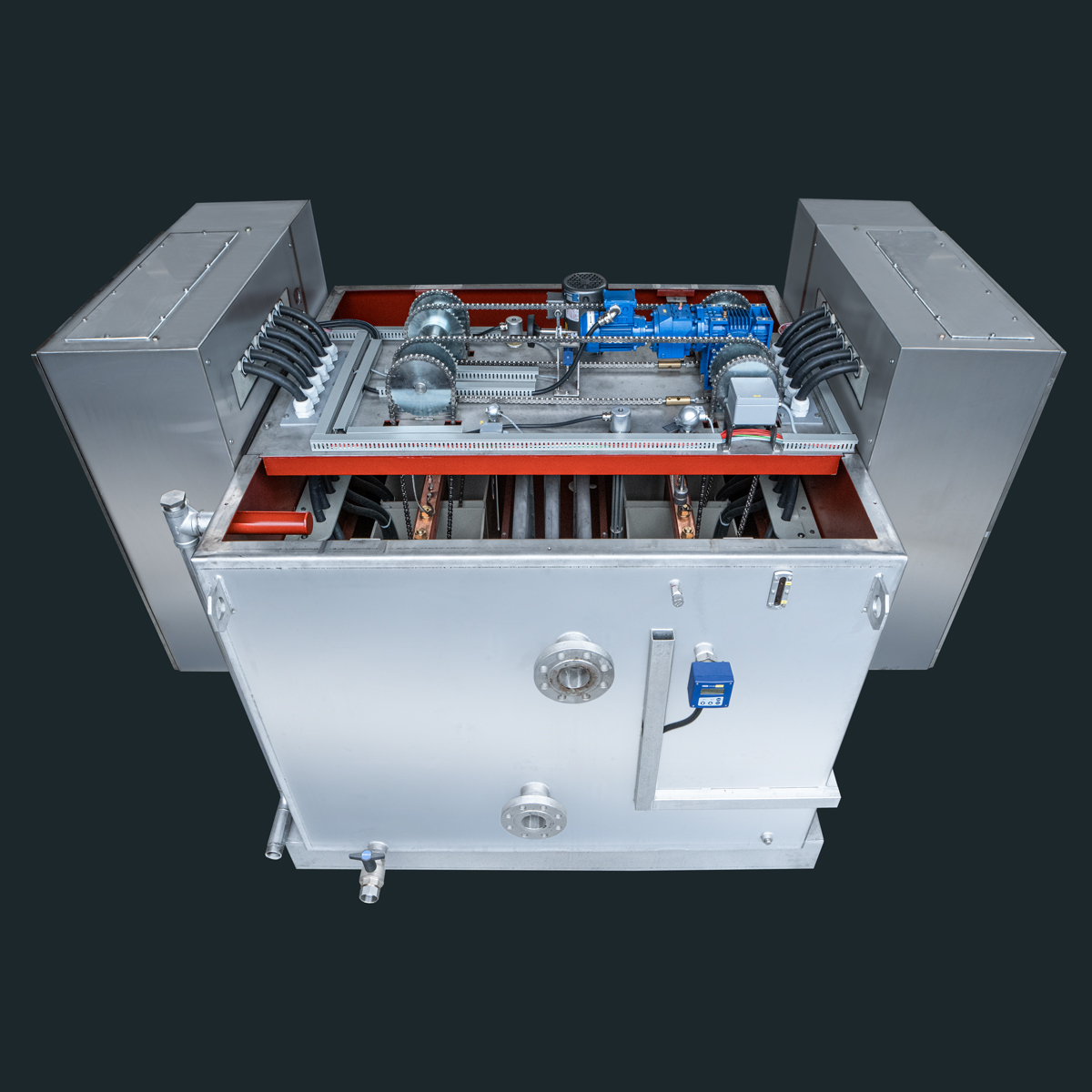

DAFA-35

liquid starter

The new liquid starter design for mining industry – It already received the CSA label and will be used at ArcelorMittal site in Canada. This one has a unique design as a dual LRS but build in one tank. Dual application Mill drives operate through a reduction gear unit and cannot be coupled electrically due to the mechanical coupling of the grinder. With a MKS dual liquid resistance starter design, every motor operating in parallel has its own electrode system that prevents large overloads from occurring in the drive or in the mill gearing. The highest levels of precision are achieved for the resistance values by keeping both electrode systems synchronised and by maintaining a constant electrolyte temperature and concentration. As both electrodes systems installtion is in one tank, those will be drive by only one drive and controlled by the same limit switch. All features above guarantee that both mill drives will be started and shorted with exactly identical resistance.

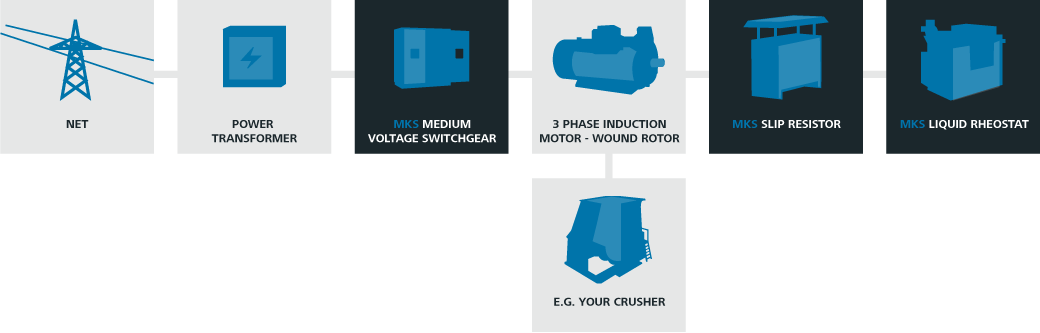

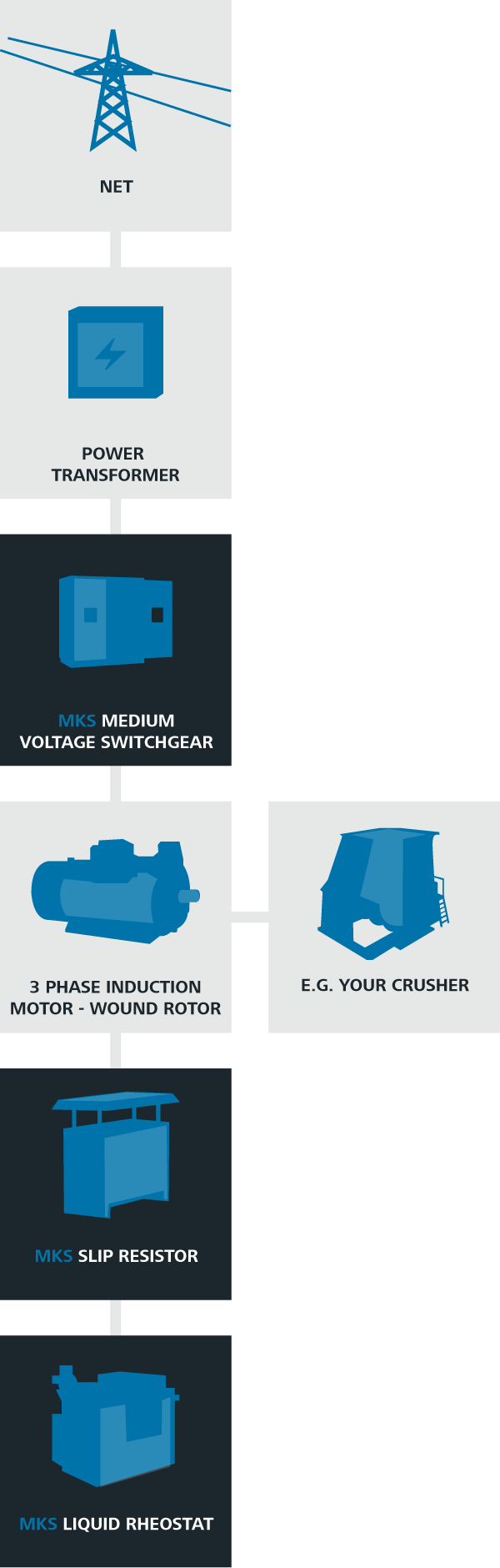

PRINCIP

Our full service solution for your drive system

We supply the components for your drive system – liquid starters, switchgear and slip resistors, which we tailor to your needs.

1. All from one Hand

From quoting through project planning to delivery, our customers are supported by a contact person who takes over the coordination and execution of the entire project.

2. Individual + specific

With our know-how and our experience, we face all challenges, however special they may be, and always find the ideal solution for your company.

3. Own production

Our liquid starters and medium voltage switchgears are designed, built and tested by our qualified MKS employees in-house in Germany.

4. Best components

All materials and equipment comply with IEC and VDE standards. Other standards can be implemented at the project level.