MKS WOUND ROTOR SLIP RING MOTOR

for shredder application

- Reinforced housing construction, direct derivation of the air-gap torque over the fixing of the stator lamination

- Reinforced welding seams of the housing construction

- Reinforced radial fixing fuse of the rotor lamination on the rotor spider shaft

- Enlarged air-gap

- Additional bandages to fix the winding overhang of the stator winding

- Reinforced bandage to fix the winding overhang of the rotor winding

- Reinforced bandage of the rotor winding derivation on the shaft

- Reduction of the shaft deflection by increasing the numbers of the spiders

- Additional fixing of the cooling pipes of the air/air cooler

- Larger antifriction bearings should be executed with solid brass cage

- DE Bearing executed as self-aligning roller bearing

- DE and NDE bearing shields should be additionallyreinforced with welded braces

- DE and NDE bearing shield dowelled additionally

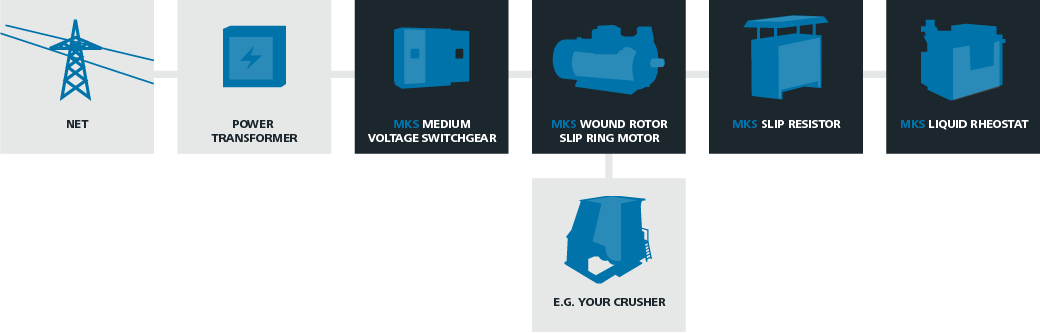

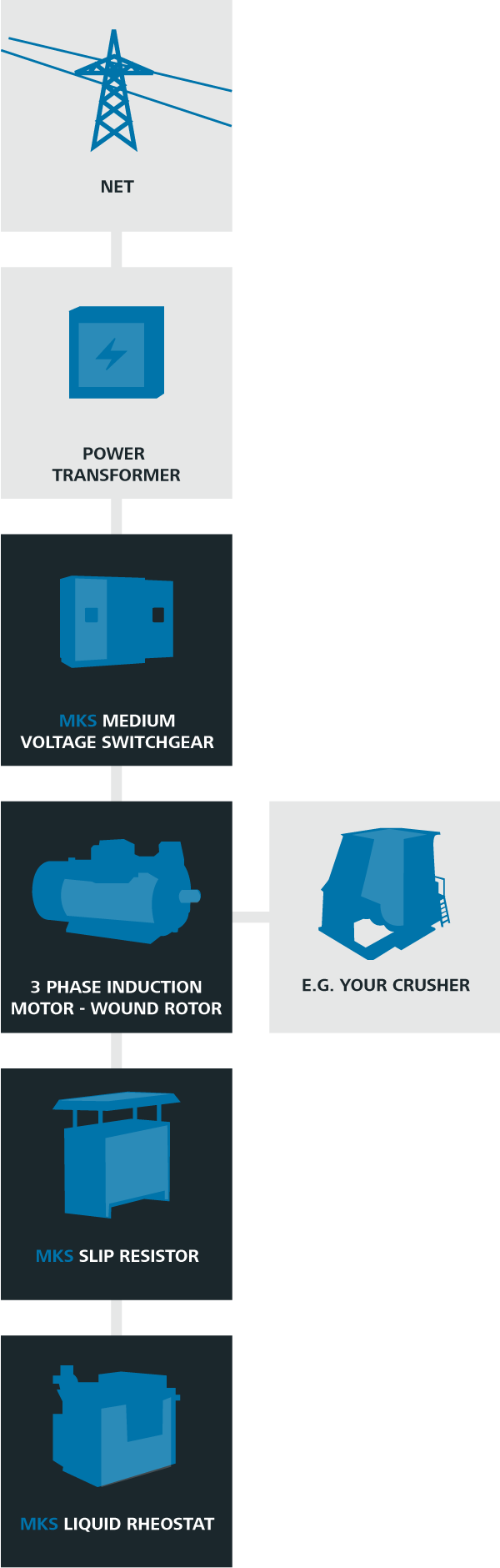

PRINZIPLE

Our full service solution for your drive system

We supply the components for your drive system – liquid starters, switchgear and slip resistors, which we tailor to your needs.

1. All from one Hand

From quoting through project planning to delivery, our customers are supported by a contact person who takes over the coordination and execution of the entire project.

2. Individual + specific

With our know-how and our experience, we face all challenges, however special they may be, and always find the ideal solution for your company.

3. Own production

Our liquid starters and medium voltage switchgears are designed, built and tested by our qualified MKS employees in-house in Germany.

4. Best components

All materials and equipment comply with IEC and VDE standards. Other standards can be implemented at the project level.